Project Description

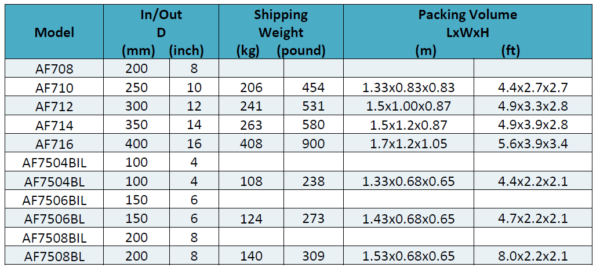

AF700 – 7500 SERRIES AUTOMATIC ELECTRIC BRUSH FILTERS

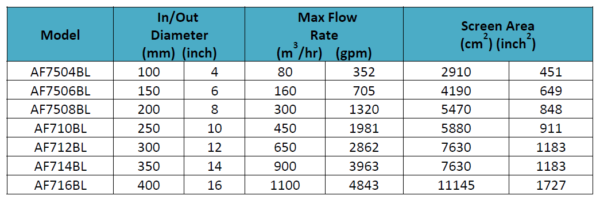

* Maximum recommended Flow Rate – 200 micron in good quality water.

**flushing flow rate data is for minimum operational pressure 1 bars (14.5 psi).

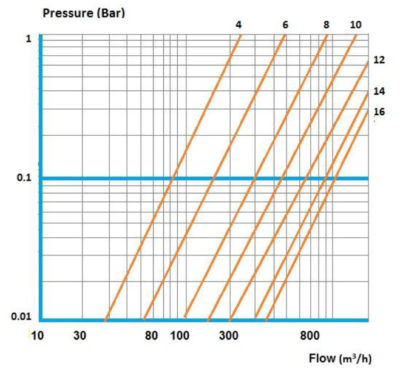

* Pressure loss at 200 micron.

Applications: Compact screen filters with automatic back flushing

Standard Characteristics:

- Filter element: – Stainless Steel screen AISI 316 mesh, supported by a PVC cylinder.

Optional – multi layered Stainless Steel Screen

- Available filtration: from 200-3000 micron

- Filter housing material of construction: Carbon Steel ST37.2

- Pre-treatment: sand blasting up to Sa 2.5 grade

- Exterior & Interior coating: electrostatic oven baked polyester-epoxy powder coating with a thickness of 150-200 micron

- Connections: VIC, Threaded socket and Flange

- Maximum recommended working pressure: up to 10 bar (145 psi).

- Minimum operating working pressure during flushing: 1 bar (14.5 psi)

- Equipped with an electronic control system 110V, 220V or 380-440V 3-phase, 0,25 HP

Operation:

Cleaning of the screen is performed automatically once the pressure loss (ΔP) across the filter has reached the preset value up to 0.5 bar (7psi). The flushing valve opens, and debris laden water is discharged through the flushing valve. The electric motor rotates the Brushes and as a result the brushes traverse the entire screen removing trapped debris. The entire process lasts for just a few seconds

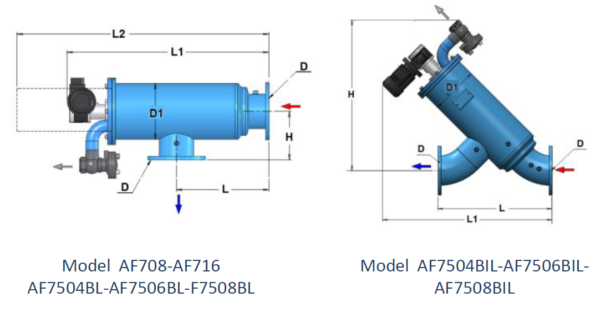

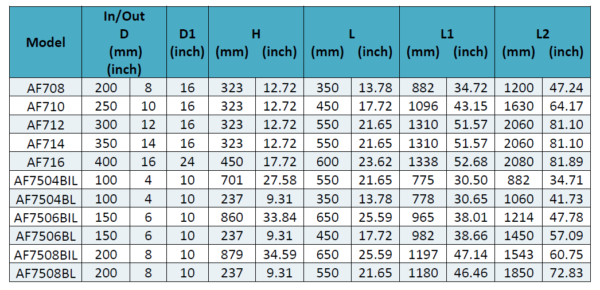

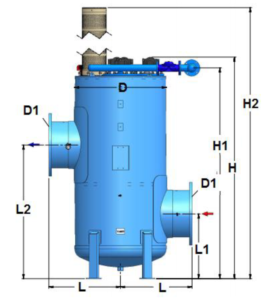

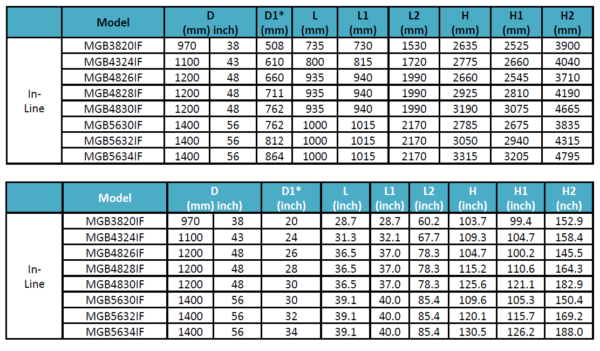

*Dimensions are only for information. Ask for latest drawings with serial code from “Solid Group”.

*For only general information.

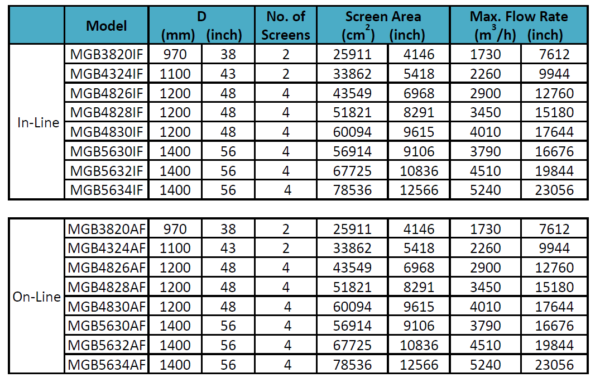

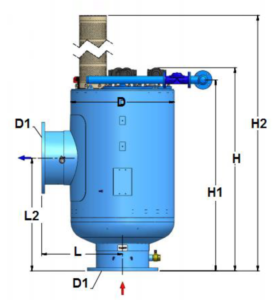

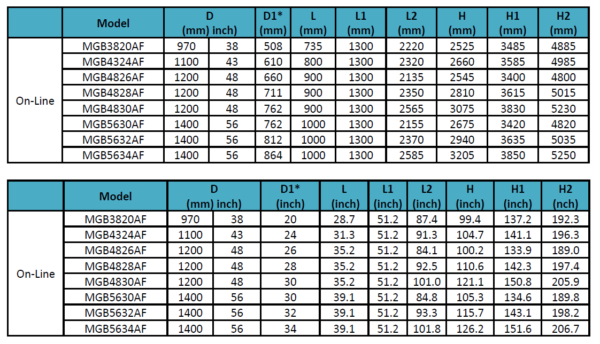

MGB SERRIES MEGA AUTOMATIC ELECTRIC BRUSH FILTERS

* Maximum recommended Flow Rate – 200 micron in good quality water.

Self-cleaning process – “Flushing“

The system continuously supplies treated water during the self-cleaning process. When waste accumulates on the filtration screen a difference in pressure between the Inlet and outlet is built. This differential pressure triggers the cleaning cycle sequence. During the cleaning cycle the control unit issues a command to open the flushing valve. Pressure is released from the inner side of the fine screen , the electric motor simultaneously rotates the brushes around its axis. The brush wipes all the dirt and efficiently cleans the entire internal screen surface. At the end of the 10 second cycle, the flushing valve closes and the operation of the electric motor is stopped. The filter is now ready for the next cycle, with clean and filtered water flowing through the “outlet”. The 10 second flushing cycle resumes operation whenever the difference in pressure reaches the preset pressure value set on the differential pressure indicator. If the pressure difference remains unchanged after one cycle, another cycle will start after a delay of 10 seconds.

Each Big filter contains 2 or more screens in one filter body. The flushing process can be programmed (on request) to work either each screen separately or in pairs.

Filtration degree: from 200-3000 micron

IN-LINE

*Dimensions are only for information. Can be changed according to the flowrate. Ask for latest drawings with serial code from “Solid Group”.

ON-LINE

*Dimensions are only for information. Can be changed according to the flowrate. Ask for latest drawings with serial code from “Solid Group”.